More About Aws Cwi

More About Aws Cwi

Blog Article

The smart Trick of Aws Cwi That Nobody is Discussing

Table of ContentsWhat Does Aws Cwi Do?Excitement About Aws CwiSome Ideas on Aws Cwi You Need To KnowThe 10-Minute Rule for Aws Cwi4 Simple Techniques For Aws Cwi

Have you ever took into consideration an occupation as a welding assessor? A welding assessment qualification is not just an excellent achievement, it verifies your abilities in the welding industry.Coming To Be a Qualified Welding Inspector reveals your commitment to expanding within the welding sector. This qualification is one that need to not and will not be overlooked! As a CWI, you'll have the ability to benefit from a number of different opportunities among market experts.

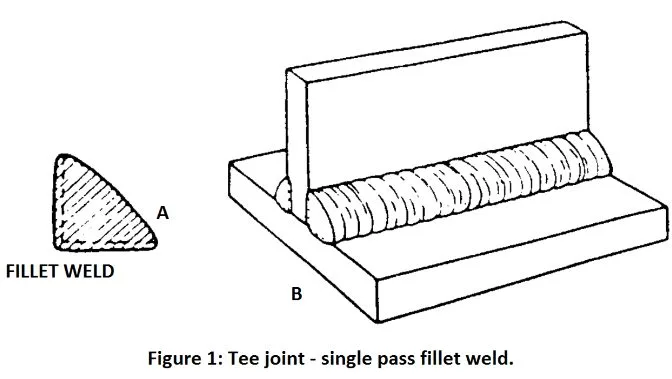

As you may understand, welding is one of the most complex solutions within the metal fabrication industry (https://www.metooo.io/u/awscw1w3lding). The end result of every welding task is highly reliant upon private welder ability.

A Biased View of Aws Cwi

There's no question that CWIs assistance to copyright better degrees of uniformity and top quality to the welding divisions they manage. This article gives a brief introduction of the main advantages of working with a steel manufacture company that employs licensed weld assessors. It's not unexpected that the majority of high-profile industries will certainly require you to hire certified welding inspectors to look after welding.

Certified welding examiners have years of experience and hence, they recognize the nuances of conformity with welding codes. Following the welding process, CWIs can carry out a series of test to examine the top quality of a weld, including visual assessment, warm therapy and a hydrostatic test. Certified Welding Inspection. They can additionally make the appropriate modifications to the pre-weld prep work and the in-weld treatments as necessary

An in-house licensed welding inspector will have the ability to ensure that your task is customized to all the requirements of appropriate welding codes, ensuring its high quality. Welding inspectors can assess welding procedure specs, structure and welding plans, devices calibration and welding materials. A welding examiners capacity to give welding procedure requirements provides the steel fabrication firm a substantial edge of the competitors, enabling fabricators to design welds that best match specific components, rather than utilizing tried-and-true welds.

What Does Aws Cwi Mean?

As previously pointed out, a CWI is not only liable fore composing the procedures for the weld, however also the quality-check screening procedures. https://www.figma.com/design/FRiLRXmmMFRuQGEzI6ECVz/Untitled?node-id=0-1&t=qzFSvhIwQu3JIjUn-1. Past that, welding examiners function to make certain that devices is properly prepped for the work which welders have the ability to complete their welds with skills (Weld Inspection). A qualified welding assessor will have had years of experience, which a metal manufacture company can take advantage of to ensure outstanding outcomes for all manufacture jobs that involve welding

This is why it's important to locate a welding company with an experienced and very trained in-house certified welding assessor on personnel. CAMM metals is such a business, so contact us today if you have a future task that requires high quality personalized welding! It's clear that a personalized metal fabrication vendor with internal CWIs has actually committed to investing in the quality of its welds.

Some industries need CWIs to be involved in the manufacturing of parts. In the end, CWIs presume rather a bit of obligation, yet their experience displays in the end product. Below at CAMM Metals, after the welding section of the project is complete, we provide lots of internal services. These services consist of weld evaluation with color penetrant, acid cleansing and polishing of stainless-steel welds.

For those clients who call for licensed welds, we can accredit our welds to AWS D1.1 & AWS D1.6.

Unknown Facts About Aws Cwi

It's vital to note that numerous employers don't always need welders to be certified. The primary distinction is that qualified welders have actually written documents of their examination outcomes and their efficiency is continuously checked with regular evaluation( s) being component of the efficiency record for each welder.

Before taking the test all PFS welders are trained, if required, in the real welding procedure that they will be utilizing and they will certainly need to have a functioning expertise of the welding equipment, welding consumable and the material to be welded. Successfully passing one test will permit the welder to service many kinds of fabrications Will certainly not permit him to work on all kinds of construction as there are qualification varies imposed for each test configuration.

Necessary variables consist of yet are not restricted to material type, consumable type, material density and welding setting. and so on. After the welder has actually finished his test plate or pipeline the weld is checked utilizing the complying with NDE procedures: Visual Examination X-Ray Liquid Penetrant Screening Sometimes, the weld is also destructively evaluated.

Aws Cwi for Dummies

PFS completes this making use of a continuity report that details all welds that a welder makes. If a welder does not use the welding procedure in a 6-month period, after that they will be requalified because procedure. The benefits to making use of an accreditation system are lots of yet the major advantages are: It confirms the ability of a specific to execute based on a certified welding procedure specification (WPS) to produce an excellent weld.

Report this page